|

1. Making Your Own CardboardIf you sell ephemera, booklets, etc., you already how important it is to protect these items against mishaps like bending and creasing in transit. There are various methods of doing this, but one of the cheapest and easiest is to use what you may already be using for simple book packaging - b-flute, a corrugated packaging material with skin on one side only. The great advantage of b-flute is that it's flexible. It can be readily rolled around a book and stapled on the ends for secure and safe packaging. However, this works well only if the items packaged (hardcover books, for example) are sturdy enough to offset this flexibility. Package a flexible pamphlet with the same method, and you're asking for trouble. Stapling the ends stiffens the package considerably, yes, but not to the extent that a carrier can't bend it to fit inside a small mailbox. Fortunately, this is easily remedied by rolling the item, cutting the b-flute and securing it with tape, then turning the resulting package 90 degrees and rolling it again. Orienting the corrugations at 90-degree angles to each other increases strength dramatically. For most purposes, this works quite well.

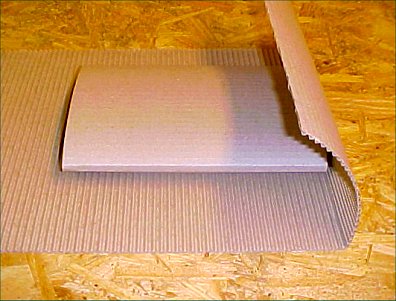

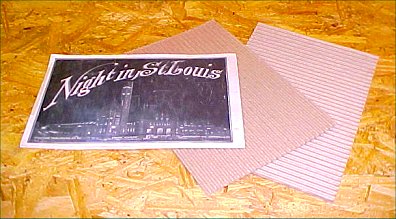

If there's a problem with this, it has to do with increased package size. If you're shipping a booklet internationally, for example, and need to fit an item inside a Global Priority envelope to take advantage of the flat rate, this could be a problem. In this case, I make my own cardboard, again with b-flute. Using a paper cutter I cut four rectangles slightly larger than the item, two with corrugations oriented in one direction, two in the other, make a sandwich, and seal it with the item in a poly bag. It works great and increases the size of your package only marginally.

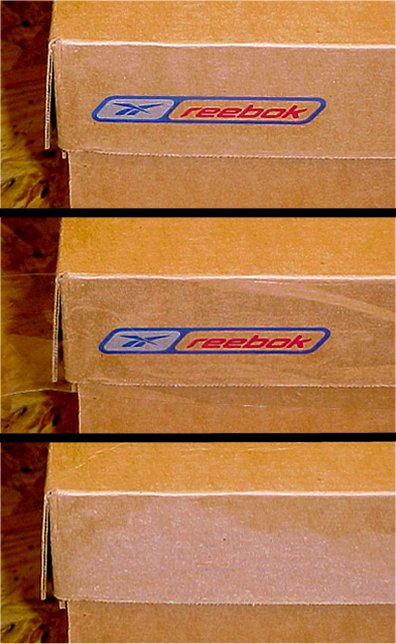

2. Disappearing Logo TrickThough I use b-flute for over 90% of the items I ship, occasionally it's convenient (especially with book lots) to use recycled boxes. The down side of this is that, in order to comply with USPS regulations, any logos, business names, etc., appearing on the outside of the box need to be concealed. This can be done easily enough with brown packaging tape or with a large marking pen. Since I use clear packaging tape for every other purpose, however, buying a second kind of tape doesn't appeal to me, nor does a box that's been defaced with black marking ink. To me, it doesn't look professional. A simple solution is to remove the offending logos. How? With clear tape. Simply tape over the logo, taking care that it's firmly adhering in all places to the cardboard, then grab one end it and rip it off. Quickly. The more quickly the better. 9 times out of 10 this will strip off a thin layer of surface material - and voila! The logo is gone.

3. Book Repair in TransitSpine deformation in books, variously described as cocking, lean, twist and roll, is a flaw that can often be corrected by simply manipulating the text block into a position opposite the one it naturally falls into, pushing it slightly beyond the point at which resistance is met, stabilizing it with clamps, and waiting a few hours or (sometimes) days for things to return to square. The original deformation isn't eliminated, of course, but the presence of new deformation in the opposite direction balances things out so as to give the book a better, closer to square, appearance. If a book is seriously deformed, fragile, or perfect bound with a glue that has become brittle, it's probably best to do nothing. Introducing further deformation to a binding that has already lost some of its integrity will often make things worse. If the binding is tight, however, it will usually remain so, or reasonably so, at the completion of this process. As in all repairs, practice on your excess copies of microwave cookbooks first and under no circumstances attempt this with a valuable book. If your deformed book is distinctly not valuable, it doesn't make sense to spend time repairing it with the above method, but a simple, much faster technique may be used in the packaging process to accomplish the same result. After sealing the book in a poly bag, manipulate it into position, clamp it on both ends, making certain that the edges of the boards or wraps are parallel, and wrap the center with packaging tape.

Remove the clamps and complete packing. The tape then behaves as a clamp during shipping, and by the time it reaches your buyer, it's likely that it will much closer to square than when it left.

< to previous article

Questions or comments?

| Forum

| Store

| Publications

| BookLinks

| BookSearch

| BookTopics

| Archives

| Advertise

| AboutUs

| ContactUs

| Search Site

| Site Map

| Google Site Map

Store - Specials

| BookHunt

| BookShelf

| Gold Edition & BookThink's Quarterly Market Report

| DomainsForSale

| BookThinker newsletter - free

Copyright 2003-2011 by BookThink LLC

|

|