|

Low-Cost, Sturdy Shelving

|

Part I: Options

Some of you may recall that, in a former lifetime, I designed and built furniture. For one reason or another, I probably built more shelving - or bookcases - than anything else.

After you've built your first 100 or so bookcases, you get a feel for what works and what doesn't; after 1,000, you don't even have to think about it anymore. You just know, usually

at a glance, even if you're looking at something you didn't build yourself.

Booksellers have special needs for shelving. Walk into your neighborhood Wal-Mart, and buy a bookcase kit constructed of melamine - a vinyl-surfaced MDF or particle board - and those

needs will be far from met. Unless you're a MMPB dealer, books are heavy. And booksellers have this tendency to fill entire shelves with them. Ironically, most ready-made shelving isn't

adequately designed to hold books - or at least very many books. Either the dimensions are whacked out (unsupported spans are too wide from side to side), the materials are inferior,

or both, and it's usually both. The Wal-Mart version won't even perform well with paperbacks. Over time, this kind of shelving will actually sag under the weight of its own shelf members -

that is, it doesn't even need to be loaded to fail. And don't even get me started on moisture issues.

One of the reasons many shelving units aren't designed for library-level use is that most buyers don't use them exclusively for books or other heavy objects, and designers who are under

pressure to cut costs know this. Lighter items such as electronic components, decorative pieces, etc., often find themselves on shelving, and books may be few and far between. So why over-build?

Of course, cost is another reason. Generally speaking, particle board is the cheapest (coated varieties coming in slightly more than uncoated), followed by MDF (medium density fiberboard),

plywood and, at the top of the heap, solid wood (though furniture-grade plywood can be obscenely expensive).

Sure, there are other options besides wood or wood products. Metal shelving units, for example, sometimes in combination with particle board; plastic shelving units; glass, and so on.

Most metal and plastic shelving units I've seen, however, aren't suitable for heavy use, despite being advertised as heavy duty. Load them with books, and inevitably shelves sag, if not

immediately, soon, and sometimes things break outright - and these units aren't exactly gorgeous to look at either, though they're more palatable in a garage next to a workbench. Glass,

in thicknesses sufficient to support this kind of weight, is prohibitively expensive, as are library-grade metal solutions.

The Pull Test

I should concede that metal and plastic shelving is getting better. Home Depot currently markets fairly good examples of each - in fact, I just got back from investigating current products

and prices. However, before sinking money into one of these, I urge you to conduct two simple tests. If there's a floor model available, lay a rigid ruler (or something similarly straight) parallel

to and near the front edge of one of the shelves, then grip the front-middle of the shelf with your hand and pull down as hard as you can. Unless you're exceptionally strong, you won't be

able to exert any more downward force than a shelf full of heavy books would, probably less. Now, if there's a significant amount (1/4" or more) of daylight between the ruler and the top of

the shelf, this foretells what will immediately happen after you load it with books - and the result will probably be worse and get worse over time.

The Rock Test

The next test is even simpler. Grab both edges of the end panel as close to top of the shelving unit, push down and attempt to rock it back and forth. Depending on how stiff (or not) the

unit is, this will give you a good indication of how quickly (or not) the shelving joinery will fail. (See below for more details.)

Sagging

Before I get to what I found at Home Depot, let's talk about sagging. It ain't good on three counts. First, the more a shelf sags, the steeper the angle your books will stand at, and books

standing at angles, even slight ones, will deform over time. Not an issue if you turn your inventory every month or two, but the more you focus your business on collectible books the longer

your turn rate will be, and the longer they will be on your shelves. If it's as much as a year or more, watch out.

Second, shelving that sags is not as durable as shelving that doesn't. There's movement, for one thing, and movement means stress to whatever joinery has been used to fasten things. If the

material is MDF, particle board or some other man-made material, the joinery hardware will pull out under stress in a relatively short period of time. Even if the shelving is hardwood or

plywood, if not designed properly, things will loosen and eventually fail. What I'm getting at here is cost. You will spend less money in the long run if you start with sturdy shelving.

Finally - and I stress that this is my opinion only, though I believe there is a strong basis for it - shelving (or any furniture) that sags in a place of business, even if it's your home

bookstore, may well have a sagging effect on one's psyche, not to mention negatively affect a customer's perception of how things are being run. To my eye, it has an unkempt, almost neglected

look, and the first thing that occurs to me when I walk into a bookstore with sagging shelves is that something else is sagging in this business as well. No doubt there are those who see a

certain charm in this sort of thing, especially if the bookstore has been in business forever, but I think you know what I mean here. Building a successful business should include putting your

best face on things, something that will elicit a sense of being paid attention to, maintained, etc. Appearance matters.

Examples at Home Depot

There were about a dozen floor models of various types of shelving at my local Home Depot - metal, plastic, MDF core (or some man-made material core), ventilated shelving - and some of these

materials were in combination. I have to tell you that every one of them in varying degrees failed the pull test except one. Here is a close-up of the corner of an Edsal brand unit that passed

the test (though all other Edsal models failed):

The difference is the strength of the members supporting the shelves. This unit was only somewhat stiff when I rocked it; shelving of this ilk is notoriously unstable unless it's anchored

into a wall or otherwise stiffened with some sort of after-market solution. It did fail a practicality test because of the projecting metal lips around the shelves. Can you just imagine banging

the bottom of a book on one of these? Thicker panels could be inserted to overcome this, but of course the price would go up significantly. Also, two of the panels in the unit I looked at

had already been broken. Hmm.

It's worth noting that it will help matters significantly on units that fail the pull test if you affix plywood cut to size on top of the existing shelves, "affix" meaning screwed into the

frame - ¾" plywood, in fact, will eliminate most and perhaps all sagging, depending on the load, but unless you have access to free or exceptionally cheap plywood, the cost per unit will nearly

double - and it won't address the rocking issue. In any case, no matter what you do to strengthen the shelves, once these units are fully loaded with books, they are significantly less stable

overall. You can push on either side with your hand and rock them back and forth. Push too far and things will collapse. Over time, also, strength will diminish further.

Also keep in mind that there are aesthetic issues with plastic or metal. Apart from their industrial appearance, which may or may not work for your bookshop area, these have poor shape memory -

that is, any deformation that occurs will likely be permanent when loads are removed. The same is true of particle board and MDF. Solid wood and plywood, on the other hand, have at least

some shape memory because of their fibrous nature.

Wall-mounted brackets in combination with plywood or solid-wood shelving is another option. As long as the standards (or brackets) are spaced fairly close together, shelf sagging shouldn't

be an issue, but wow, what an inefficient use of space. This type of shelving eats up wall space (and, indirectly, floor space) by the yard in no time and offers no portability whatsoever. In

the past, I've also used ventilated shelving - that vinyl-coated junk you see mounted on walls in lots of closets. Talk about deformation. It might work ok if you spaced the standards every

six inches or so and screwed some plywood to it, but who wants to mess with that? And you'd still be left with the same space and portability disadvantages.

So - what's the best answer for booksellers? Certainly furniture-grade plywood and/or solid wood bookcases are somewhat to very expensive to buy ready-made, and this is assuming that they're

designed to hold the loads you'll be dumping on them in the first place - a big assumption - but if there was a simple method of constructing wood shelving yourself with relatively low-cost

materials, a well-designed unit would not only support loads on the order that we're talking about without significant deformation but also cost only somewhat more than so-called heavy-duty plastic

and metal shelving. And last virtually forever. Moreover, if aesthetics were an issue, you would have the option of finishing it in any color and/or adding decorative elements to it.

The purpose of this series of articles is to suggest such a method. Before you dismiss the idea of a do-it-yourself approach, perhaps thinking that you're all thumbs when it comes to building

anything at all, I urge you to keep an open mind. Over the years, I've constructed furniture using nearly every joint known to mankind - dados, dovetails, dowel joints, interlocking joints, lap

joints, mortise and tenon, and many more. The joint I'll be proposing in Part II of this series is unlike any of them in that an exceptionally strong connection can be accomplished in a matter of

moments - and all one needs going in is a power drill and a fairly low-cost jig.

I'll discuss this joint in Part II of this series, present various designs in Part III, and propose a simple, professional-level finishing technique in Part IV. Somewhere along the way I'll show

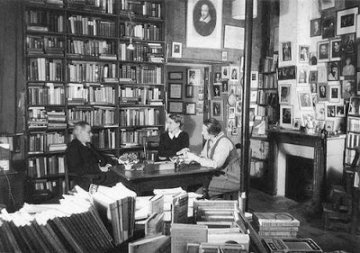

you how to get lots more storage per square foot with your shelving than you might ever have imagined. Meanwhile, have you ever looked at early photos of Sylvia Beach's legendary Shakespeare and Co.

bookstore? Glance at the shelving behind T. S. Eliot here, and note total absence of sagging.

< to previous article

to previous feature article >

Questions or comments?

Contact the editor, Craig Stark

editor@bookthink.com